The Surface Solutions | How Coating Solutions Drive Real Results

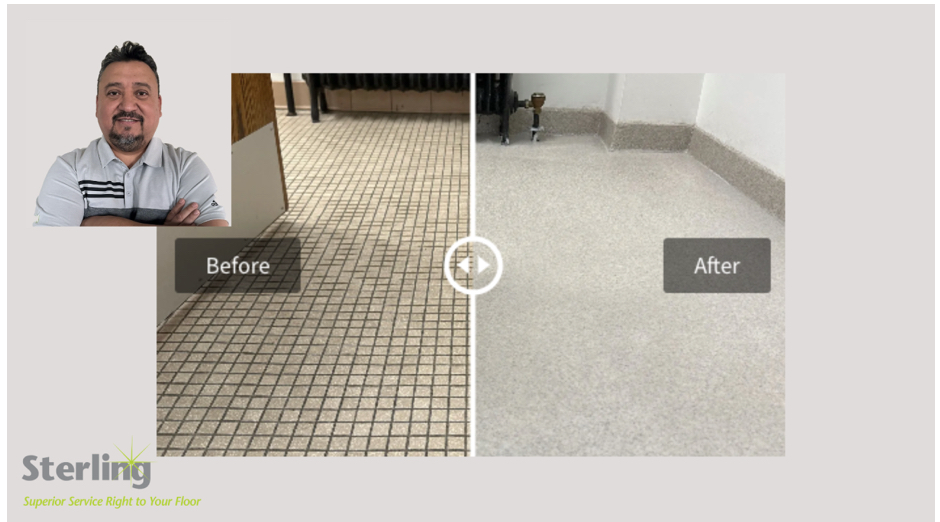

At Sterling Services, we remain focused on staying ahead of industry trends and embracing innovations that benefit both our team and our clients. Hear from Luis Moran, our regional manager in Houston, to learn about his coating inspector training and how these solutions drive results.

Across the commercial and industrial sectors, protective coatings and epoxy systems are rapidly evolving to meet the demands of high-traffic, high-performance environments. Advanced coatings now go beyond aesthetics; they’re engineered for durability, hygiene, safety, and long-term cost efficiency qualities critical in today’s healthcare, logistics, and manufacturing spaces.

A key part of delivering this performance lies in the work of certified coating inspectors. These professionals are trained to ensure coatings are applied correctly and in compliance with rigorous standards like those from AMPP (Association for Materials Protection and Performance), ISO, and ASTM. By verifying surface preparation, monitoring environmental conditions, and conducting field tests such as dry film thickness (DFT), adhesion, and holiday detection, coating inspectors help prevent premature coating failures and costly repairs.

Coating inspections are about more than checking a box. It’s about preventing problems before they happen and ensuring surfaces are prepped to spec, coatings are applied within tolerances, and conditions are right. The goal is a long-lasting system that holds up under pressure.

One of the most in-demand systems continues to be epoxy floor coating. Known for its strength and versatility, epoxy provides a seamless, waterproof surface that stands up to heavy use, chemical exposure, and regular cleaning. Unlike traditional flooring materials, epoxy is low maintenance, highly customizable, and available in a wide range of colors and textures, ideal for branding, safety zoning, or aesthetic enhancement.

Epoxy coatings are compatible with a variety of existing surfaces, including concrete, tile, wood, linoleum, metal, and previously coated floors. This adaptability makes them a go-to solution for industries where downtime and disruption must be minimized. Common applications include:

- Hospitals and healthcare facilities

- Warehouses and logistics centers

- Universities and research labs

- Military and government buildings

- Pharmaceutical and food production plants

- Retail and commercial kitchens

At Sterling Services, we don’t just apply coatings; we deliver tailored, strategic solutions backed by trained professionals like Luis. Whether you're navigating compliance standards, planning an upgrade, or solving persistent flooring challenges, we bring the expertise, inspection rigor, and innovation needed to get the job done right and done to last.